-

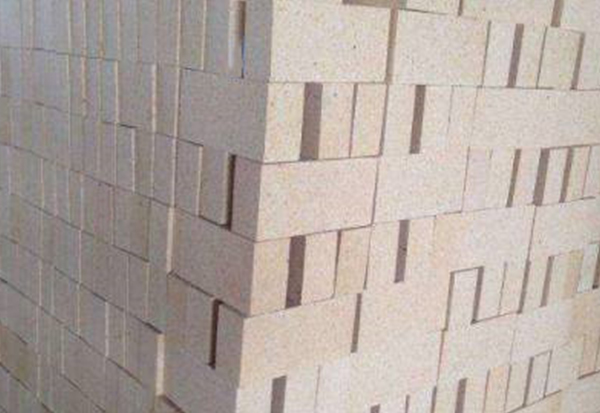

Phosphoric acid impregnated clay brick and high alumina brick

-

Press material into the furnace waist and upper part of furnace body

-

Spraying coating on the shell of blast furnace and hot blast furnace

-

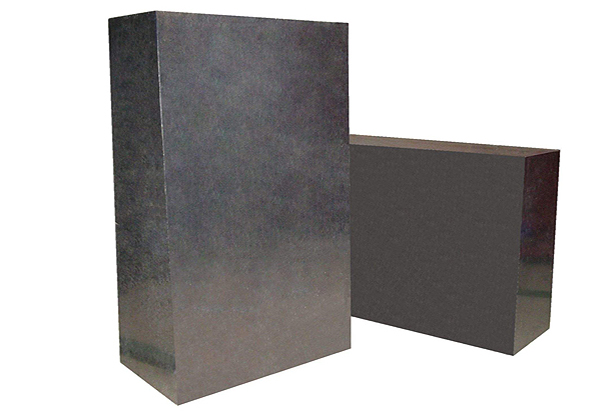

Hot shock resistant low creep high aluminum series for hot blast stove

-

Matching slurry of unburned Al2O3-SiC-C brick for torpedo tank

-

Matching slurry of fired aluminum carbon brick for torpedo tank

-

Refractories for continuous casting ladle, refining ladle, vacuum ladle and medium ladle

mobile phone:+8613903825488

Telephone:+86-371-64122052