mobile phone:+8613903825488

Telephone:+86-371-64122052

New type of hot metal pot brick:

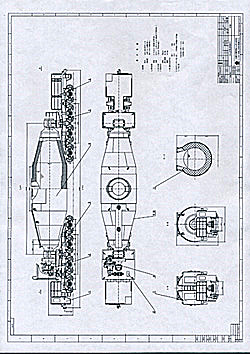

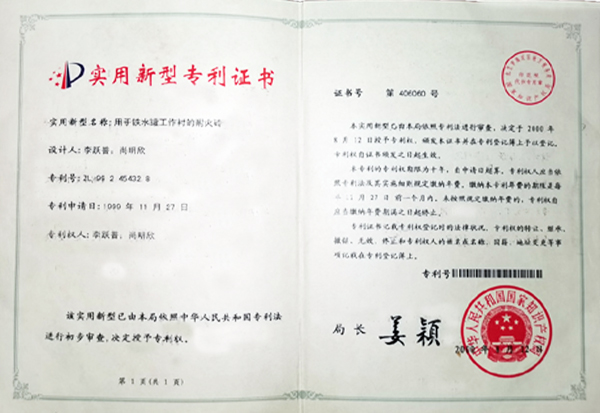

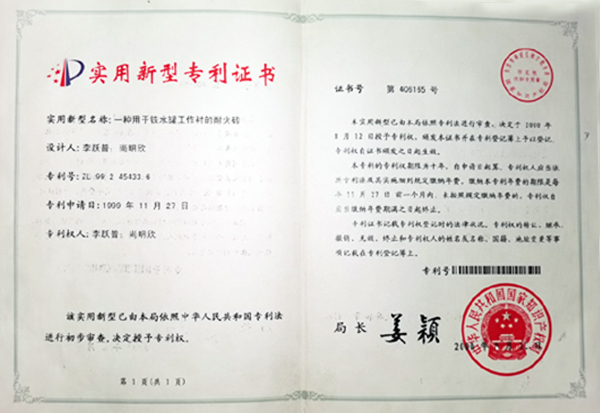

Driven by the wave of market economy, China's metallurgical industry has changed the traditional concepts and technical equipment, new products and new processes are emerging, and refractories are booming in the process of innovation. Under the leadership of director Zhang Zili and chief engineer Li Yuepu, all the technical personnel of our plant have conducted in-depth market investigation on the special equipment for ironmaking, i.e. hot metal ladle In masonry, convenience and material selection, some problems existing in masonry and use of this kind of equipment are solved, internal structural stress analysis of engineering materials is carried out, production process of overturning package is simulated on production site, data processing of computer analysis and calculation is carried out, and pre built combination of finished products is finally developed. A new type of hot metal tank brick and supporting masonry process are developed. This new type of refractory brick is made of high quality It is made of high-purity refractory materials such as scorched gemstone and high alumina bauxite. According to the inspection of Luoyang Refractory Research Institute, various physical and chemical indexes have exceeded the national standard. The process is simple and practical, 65 ton package, generally needs 2-3 days to build, and the new process can be completed within 1 day. The brick joints do not overlap, and the integrity is good without grinding and cutting. The labor intensity of the workers is low. It is used in combination with the special mud of our factory. It is scour resistant, anti invasion candle, anti peeling, small thermal conductivity, and good integrity. The service life of the 65t-90t hot metal tank is more than 1500 times, and it is reduced With less repair, the production cost is reduced. After being used by large and medium-sized iron and steel companies such as Handan Iron and Steel Group, Xuanhua Iron and Steel Group, Guanggang iron and Steel Group and Liugang iron and Steel Group Co., Ltd., the economic and social benefits are remarkable, which are well received by users.

The process is simple and practical, 65 ton package, generally needs 2-3 days to build, and the new process can be completed within 1 day

The process is simple and practical, 65 ton package, generally needs 2-3 days to build, and the new process can be completed within 1 day

(top view)

No overlapping of brick joints, good integrity, no grinding and cutting, low labor intensity of workers

No overlapping of brick joints, good integrity, no grinding and cutting, low labor intensity of workers

(crosscut)

New type of aluminum silicon carbide carbon brick for torpedo can:

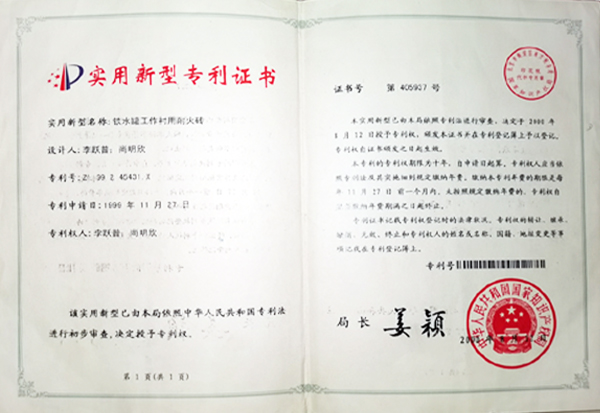

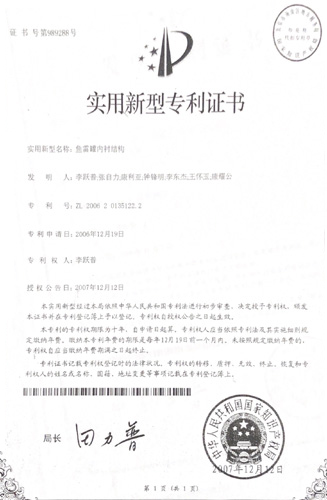

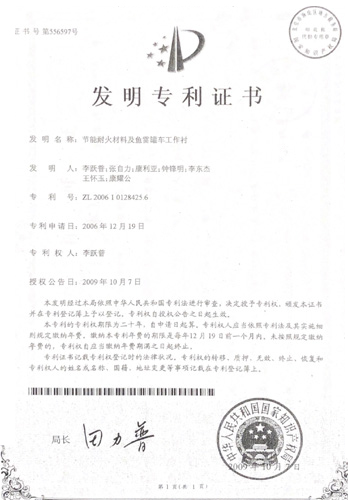

With the rapid development of iron and steel industry, driven by the wave of market economy, new equipment, new products and new processes in China's metallurgical industry are constantly emerging, and refractories are booming. Under the leadership of director Zhang Zili and chief engineer Li Yuepu, all technical personnel of our plant have conducted in-depth market investigation and conducted in-depth investigation on ironmaking Special equipment - torpedo can is used in masonry, convenience and material selection to tackle technical problems. For some problems existing in masonry and use of such equipment, stress analysis of internal structure of engineering materials is carried out to simulate the production process at the production site, computer analysis, calculation, data processing and pre combination of finished products. Finally, a new type of aluminum silicon carbide carbon brick for torpedo can is developed and matched The invention patent of energy-saving refractory material and working lining of torpedo tank car (Patent No.: 200610128425.6) and utility model patent of torpedo tank lining structure (Patent No.: zl200620135122.2) have been obtained. This new type of refractory brick is made of high-quality bauxite and a variety of high-purity refractory materials. It has been tested by the national refractory testing center of Luoyang Refractory Research Institute, and all the physical and chemical indexes have reached the national standards. The process is simple and practical. The 190T torpedo tank generally needs 2-3 days to be built. The new process can be completed within 1 day. It has good integrity and does not need to be grinded and cut. The labor intensity of the workers is low. It is used in combination with the special mud produced by our factory. It has the advantages of erosion resistance, penetration resistance, peeling resistance, small heat conduction system and good integrity. It has been used more than 1200 times on 160t-320t torpedo tank, and has reduced repair and production cost. After being used by large and medium-sized iron and steel companies such as Handan Iron and Steel Co., Ltd. and Liugang iron and Steel Co., Ltd., the economic and social benefits are remarkable, which are well received by users.

Erosion resistance, penetration resistance, peeling resistance, small thermal conductivity and good integrity

Erosion resistance, penetration resistance, peeling resistance, small thermal conductivity and good integrity

Henan Zili refractory Co., Ltd

Address: Chuangye Avenue, refractories Industrial Park, Gongyi City, Henan Province

Mobile: +8613903825488

Contact:+86-371-64122052