Introduction to the manufacturing process of some high alumina bricks

发布时间:2020-06-24

浏览:次

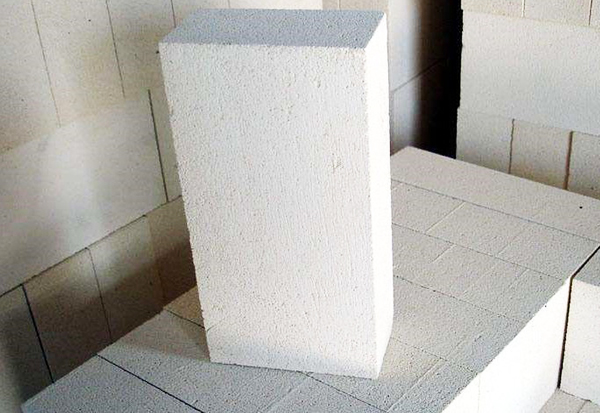

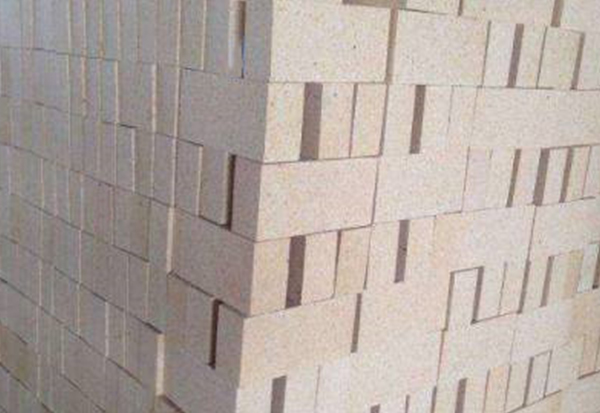

High alumina brick is a kind of refractory material. The main component of this kind of refractory material brick is Al2O3. Because of different resources, the specifications of different countries are not complete and different. For example, in European countries, the lower limit of Al2O3 content is 42%. In China, according to the Al2O3 content in high alumina bricks, there are three grades: Grade I - Al2O3 content > 75%; grade II - Al2O3 content 60-75%; grade III - Al2O3 content 48-60%

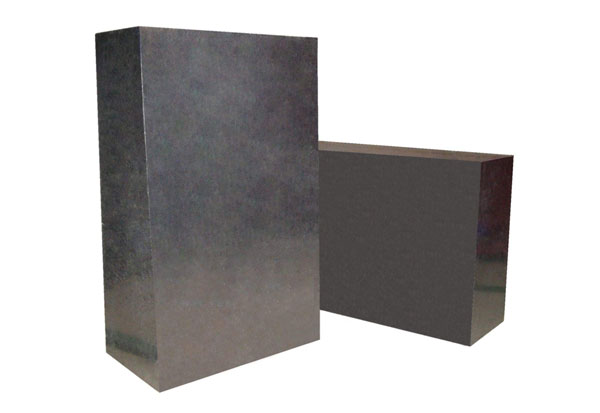

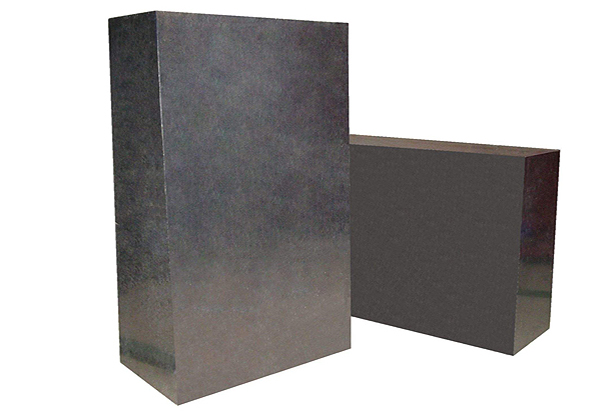

A kind of neutral fire-resistant material with alumina content more than 48%. It is made of bauxite or other raw materials with high alumina content by molding and calcining. High thermal stability, fire resistance above 1770 ℃. It has good slag resistance and is used for lining steel-making electric furnace, glass furnace, cement rotary furnace, etc. High load soft and low creep high alumina brick is made of special grade bauxite, fused corundum and fused mullite.

Manufacturing process: the consumption process of high alumina brick is similar to that of multi clinker clay brick. The difference is that the proportion of clinker in the ingredients is high, which can reach 90-95%, Before crushing, clinker needs to be sorted and screened to remove iron. The firing temperature is relatively high. For example, when tunnel kiln is used to burn high alumina bricks such as Ⅰ and Ⅱ, the temperature is generally 1500-1600 ℃. Before crushing, high alumina clinker should be strictly sorted and stored in different grades. The production and quality can be improved by using the method of fine grinding of bauxite clinker and separated clay.

High alumina brick is mainly composed of high alumina bauxite; sillimanite minerals (including kyanite, andalusite, sillimanite, etc.); synthetic raw materials, such as industrial alumina, synthetic mullite, fused corundum, etc. Characteristics: the fire resistance of high alumina brick is higher than that of clay brick and semi silica brick, reaching 1750 ~ 1790 ℃, which belongs to the advanced fire resistance data. The load softening temperature of high alumina products is higher than that of clay brick because of the high Al2O3 content, low impurity quality and less glass body which is easy to melt. However, because mullite crystal does not form network structure, the load softening temperature is still lower than that of silica brick.

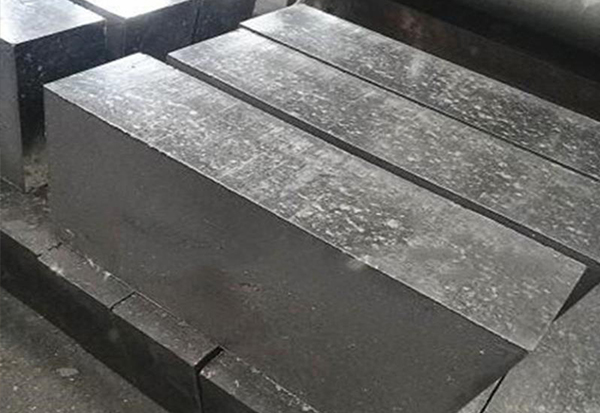

Display of Hot Products

You may be interested in the following information?