Tell you how to choose refractory castable

发布时间:2020-06-24

浏览:次

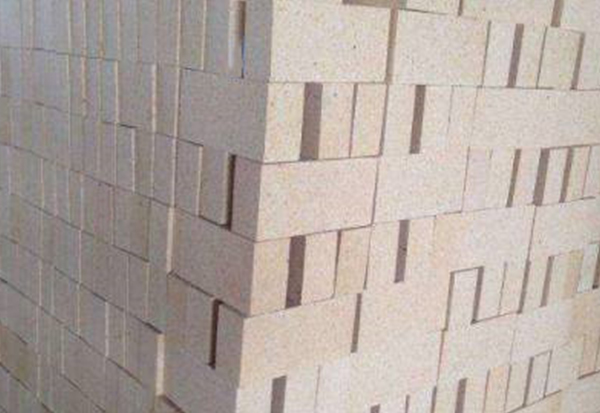

Refractory castable refers to a mixture composed of refractory aggregate, binder and admixture, which can be mixed with water (or liquid binder) to form a slurry that can be constructed by pouring method. The difference with other amorphous refractories is that the refractory castables have a certain setting and hardening time after construction. Therefore, the castables can be demoulded only after a certain period of curing, and then can be put into use after a proper period of natural curing.

The refractory castable is suitable for pouring and vibrating construction, and can also be pre manufactured into prefabricated parts with specified shape and size, which can be used to build industrial furnace lining. In order to improve the physical and chemical properties and construction performance of refractory castables, appropriate additives such as plasticizer, dispersant, coagulant, retarder, expansive agent, degelling agent and gel agent are often added. In addition, the toughness of the castable used in the place with large mechanical force or strong thermal impact will be increased significantly if a proper amount of stainless steel fiber is added. If inorganic fiber is added to the insulating refractory castable, it can not only enhance its toughness, but also improve its thermal insulation performance. Because the basic material composition of refractory castable (such as aggregate and powder, admixture, binder and admixture), setting and hardening process, construction method, etc., are similar to the concrete in civil engineering, it was also called refractory concrete.

The refractory castable has the advantages of simple production process, energy saving, high construction efficiency and good quality, and can be prepared on site or selected materials with excellent performance according to the needs. Therefore, the refractory castable is a kind of amorphous refractory which is widely used in furnace construction.

Refractory castable is composed of cementitious material, aggregate and admixture, and sometimes coagulant is added. Refractory aggregate is the main body of refractory concrete. All kinds of refractory materials (clay, high alumina, silica, magnesia, etc.) can be used as refractory aggregate after calcination of clinker or crushing of various waste bricks to a certain extent. The particle size of aggregate has a great influence on the quality of products, so there is a certain limit to the particle size of aggregate, and there is a certain proportion requirement in quantity. The refractory aggregate is equivalent to the gravel and sand of ordinary building concrete. In the proportion of refractory concrete, aggregate generally accounts for 70% - 80%. Among them, coarse aggregate (5-20 mm) accounts for 35% - 45% of the ingredients; fine aggregate (0.15-5 mm) accounts for 30% - 35%.

Cementitious material plays a role of cementation and hardening, so that the products have a certain strength. Can be used as cement: Ordinary portland cement, alumina cement (high sales Cement), magnesium cement, water glass, phosphoric acid, etc. In order to ensure that the concrete has enough fire resistance (the binder is the flux at high temperature, the more the quantity, the lower the fire resistance of the concrete), and to reduce the volume shrinkage in the use process, the amount of the binder should be as small as possible, generally 10% - 25%, and it is hoped that the binder and the bone material can not generate more low melting materials.

Some refractory concrete (such as phosphate refractory concrete) must be added with a small amount of coagulant to accelerate the hardening and consolidation of concrete. In order to improve the performance of fire-resistant concrete, such as increasing the strength in the process of temperature rise and reducing the volume shrinkage, 10% - 25% admixture is often added. The raw material of the admixture is the same as the aggregate, which is the finely ground refractory clinker powder, of which 70% - 80% fineness is less than 0.088mm

Display of Hot Products

You may be interested in the following information?