Refractory manufacturers introduce the performance and application of silica brick to you

发布时间:2020-06-24

浏览:次

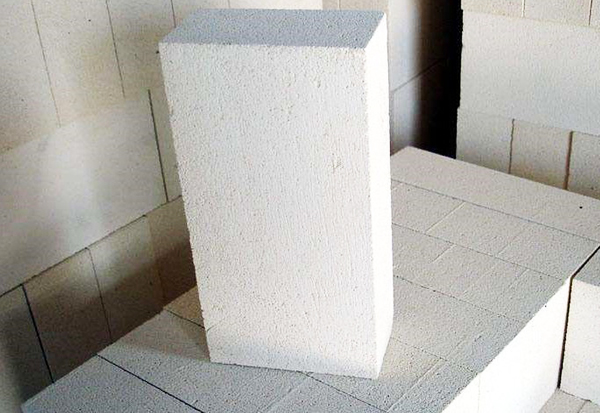

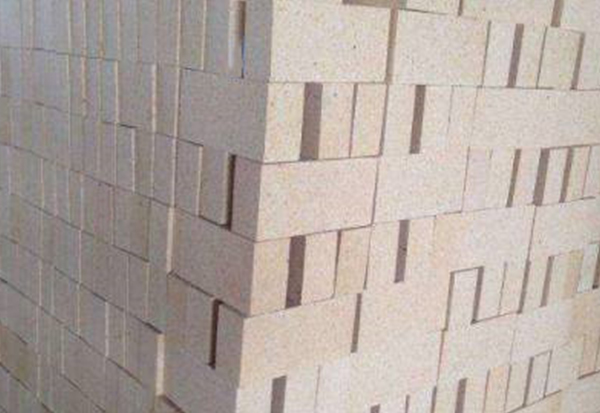

According to the physical and chemical indexes, the silicon bricks produced by our company are divided into gz-94, gz-95 and gz-96, and the product standard adopted is GB / t2068-200l. If you want to know the price of silica brick, you must know what kind of kiln it is used in. There are mainly three types:

1. Silica brick for coke oven

The silica brick for coke oven is mainly composed of tridymite, which is used to build silica refractory brick for coke oven. The modern coke oven is a large-scale thermal equipment built by thousands of tons of brick refractories, of which the silicon brick accounts for 60% - 70%. The silica brick of coke oven is used to build the regenerator, chute, combustion chamber, carbonization chamber and furnace top of coke oven. The silica brick of coke oven shall have the following characteristics:

(1) High softening temperature under load. The silica brick of the coke oven should bear the dynamic load of the coal car on the top of the furnace under high temperature, and it is required to be used for a long time without deformation, so the load softening temperature of the silica brick of the coke oven is required to be high.

(2) High thermal conductivity. The coke is made by coking coal in the carbonization chamber by heat transfer from the kiln wall of the combustion chamber. Therefore, the silica brick for the combustion chamber wall should have a high thermal conductivity.

(3) Good thermal shock resistance. The temperature of silica brick on both sides of combustion chamber wall changes dramatically because coke oven needs to load and discharge coal periodically, so it is required to have good thermal shock resistance.

(4) High temperature volume stability. The brand of silica brick for coke oven is jg-94, and the product standard is Yb / t5013-1997.

The requirements for section spalling of silica brick are as follows:

1) When the spall width is not more than 0.1mm, it is not limited;

2) When the spallation width is 0.11-0.25mm, the length is not more than 60mm

3) When the spallation width is 0.26-0.50mm, the length is not more than 30mm;

4) When the spallation width is greater than 0.50 rnnl, no spallation is allowed;

5) When the section crack extends to the brick surface, it is not allowed to have.

2. Silica brick for hot blast stove

With the increase of the air temperature of the hot blast furnace, the use conditions of refractories for the hot blast furnace are more and more severe. When the air temperature is higher than 1200 ℃, the traditional high alumina brick can not meet the use requirements of its high temperature parts. At high temperature, silica brick has the advantages of low creep rate, high strength and good thermal shock resistance. Therefore, silica brick is widely used in the top of large hot blast furnace, partition wall and upper part of regenerator.

The brand of silica brick for hot blast stove is rg-95, and the product standard is Yb / t1133-1998.

3. Silica brick for glass kiln

High quality silica brick for glass kiln has the characteristics of high silicon oxide content and low melt index. It is mainly used for the crown, breast wall, hanging wall, small furnace and other upper structures of glass kiln as well as the arch of regenerator.

The standard of high quality silica brick for glass kiln is JC / t615-1996. According to the single weight of refractory brick, it can be divided into three grades: xbg-96, zbg-96 and dbg-96.

Our company produces silicon brick with stable quality and moderate price. Welcome to visit our company!

Display of Hot Products

You may be interested in the following information?