Performance and application of low porosity clay brick

发布时间:2020-06-24

浏览:次

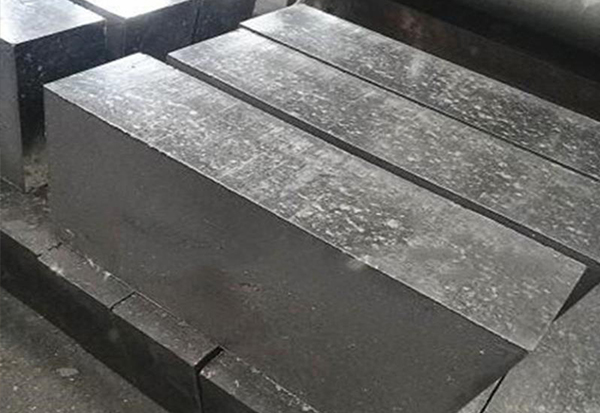

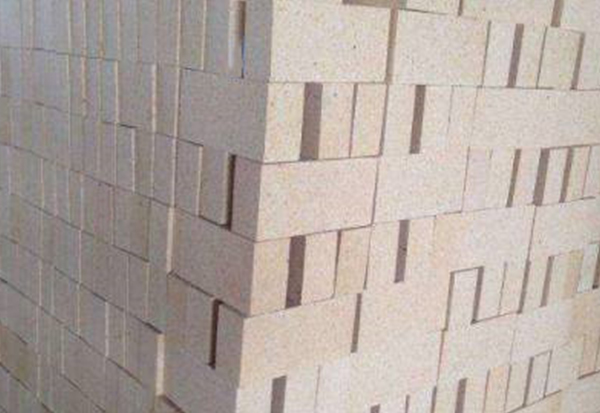

Low porosity clay brick is a kind of low porosity clay product, which is mainly made of common clay brick raw materials, adding burnt gemstone as the main raw materials, adding sillimanite and andalusite according to the proportion, adding binder and binder, mixing, forming and drying, and then firing in the kiln. The porosity is less than 17%.

The key to produce low porosity clay brick is to select the raw material with high density and low water absorption and to make it through reasonable grading. The temperature of tunnel kiln for firing clay brick is generally controlled at 1350 ℃ ~ 1380 ℃, and the firing temperature of low porosity clay brick is properly increased (1420 ℃), the shrinkage of clay brick is slightly increased, so that the density of refractory brick is slightly increased, and the low porosity is reduced.

Advantages of low porosity clay brick:

1. Strong erosion resistance;

2. Low porosity, high density;

3. High mechanical strength;

4. Strong anti permeability;

5. High strength and fire resistance;

6. Tissue density;

7. Good thermal shock stability and anti spalling.

Due to the addition of additives, a large number of micro pores are formed in the clay brick during the firing process. Before the whole fracture of clay brick, the micro pore inside the brick can prevent and restrain the fracture of clay brick. As a kind of clay brick used under high temperature thermal shock, the surface crack of the clay brick will not cause fracture in the process of use. The serious problem is the thermal spalling caused by the internal thermal stress. When the porosity is properly reduced and a large number of micro pores are generated, the length of the internal cracks of the clay brick becomes shorter, the number of cracks increases, and the degree of the cracks crisscross each other to form a network is enhanced. Therefore, the increase of fracture energy is necessary for the fracture of clay brick, which can effectively improve the thermal shock stability of clay brick, improve the peeling resistance of clay brick, and greatly increase the furnace life.

Low porosity clay is used as the lining of brick and glass kiln regenerator, blast furnace and hot blast furnace in iron and steel industry, cement kiln in building materials industry, chemical kiln in chemical industry, etc.

Display of Hot Products

You may be interested in the following information?