Advantages and application scope of phosphate high alumina refractory brick

发布时间:2020-06-24

浏览:次

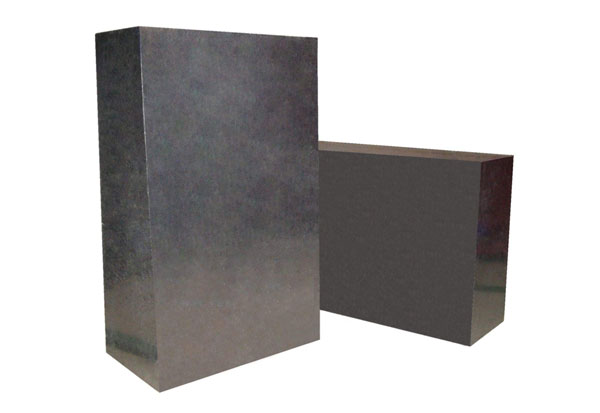

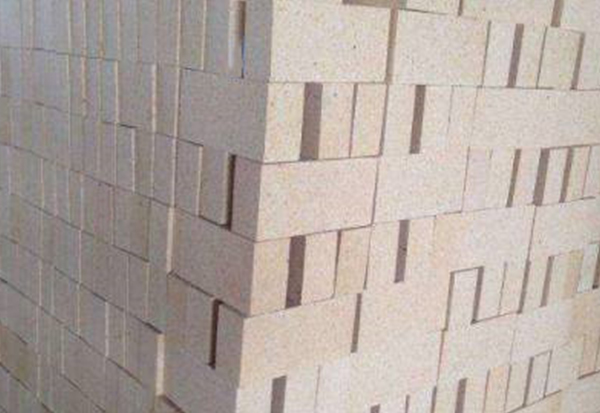

Phosphate high alumina refractory brick belongs to unburned brick, which is made of high alumina material after molding and heat treatment. It has the following advantages: high compressive strength at room temperature, good wear resistance, basically equivalent load softening temperature and semi direct combination of magnesium and chromium bricks, superior to anti peeling high aluminum bricks, and has good thermal shock stability. For the transition zone with large temperature change, its performance advantages should be clearly reflected.

Advantages of phosphate high alumina refractory brick:

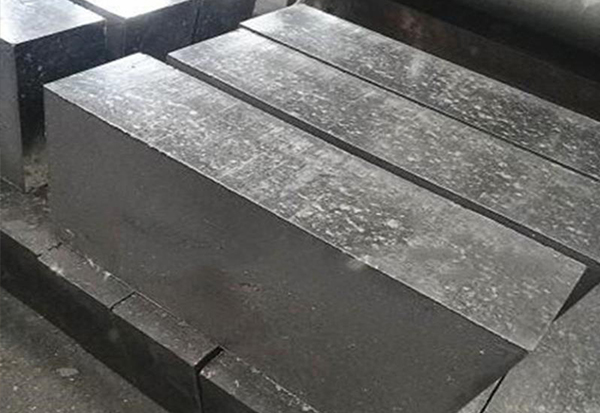

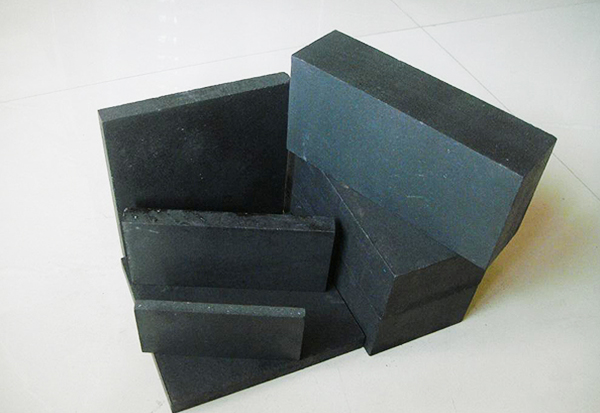

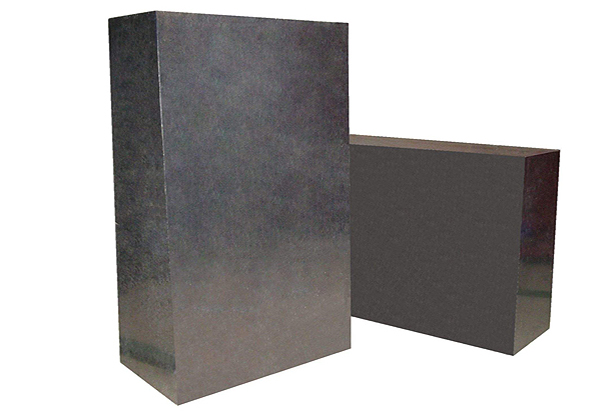

Phosphate bonded high alumina refractory brick is a kind of chemical bonded refractory product, which is made of phosphoric acid solution or aluminum phosphate solution (aluminum dihydrogen phosphate, PA-80 glue, etc.) as binder, bauxite clinker as aggregate, machine pressed and processed at 500-600 ℃. Phosphate combined with high alumina brick is short for phosphate brick, while aluminum phosphate combined with high alumina brick is short for wear-resistant brick. The latter has higher compressive strength.

There are two obvious shortcomings of phosphate bonded high alumina refractory brick, one is the low load softening temperature, about 1300 ℃; the other is the large linear shrinkage of reheating, which affects its use effect and application field. In order to solve this problem, adding three stones to the material is an important measure. As mentioned before, the three stones are irreversibly changed into mullite and SiO2 at high temperature, and accompanied by volume expansion. Using this feature, the load softening temperature of the products is increased, the shrinkage at high temperature is reduced, and the thermal shock resistance is improved.

Phosphate brick is bound by 42.5% ~ 50% phosphoric acid solution, and the aggregate is bauxite clinker calcined in a rotary kiln above 1600 ℃. In the process of using brick, phosphoric acid reacts with bauxite powder and fire-resistant clay in the brick, and finally forms a bond mainly composed of cristobalite aluminum orthophosphate. The wear-resistant brick is made of industrial phosphoric acid and industrial aluminum hydroxide mixed with aluminum phosphate solution as binder. Its molar ratio is, and the aggregate used is the same as that of phosphate brick. In the process of using brick, it is the same as phosphate to form the bond mainly composed of cristobalite aluminum orthophosphate.

Application scope of phosphate high alumina refractory brick:

The shape and size of phosphate brick and wear-resistant brick for vertical cement kiln shall be determined by the supplier and the demander. It is also superior for firing belt. The wear-resistant brick is suitable for the cooling belt, kiln mouth and cooler of rotary kiln.

Display of Hot Products

You may be interested in the following information?