Look at the difference between corundum brick and chrome corundum brick

发布时间:2020-06-24

浏览:次

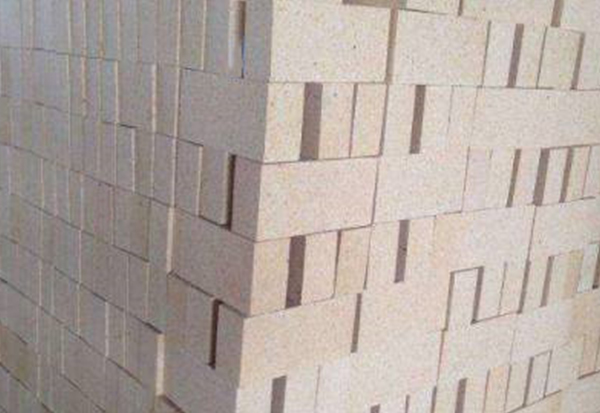

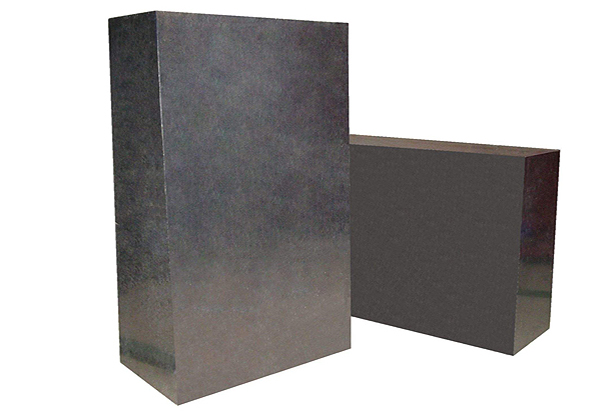

Corundum brick is a refractory brick with alumina content more than 90%. Corundum brick is divided into sintered corundum brick and fused corundum brick, while chrome corundum brick takes part in Cr2O3 refractory brick in corundum. Chrome corundum brick is divided into fused chrome corundum brick and sintered chrome corundum brick. Corundum brick is used in industrial kilns under high temperature and high pressure. There are similarities and differences between corundum brick and chrome corundum brick.

The addition of Cr2O3 to corundum materials will not only reduce the refractoriness of the materials, but also improve the refractoriness of the materials. The refractoriness of chrome corundum brick is higher than that of corundum brick at 1790 ℃ and load softening temperature is higher than that of corundum brick at 1700 ℃. The normal temperature compressive strength of pressure resistant corundum brick is 70-100mpa. The normal temperature compressive strength of high-performance chrome corundum brick is generally greater than 150MPa, which is significantly higher than that of corundum brick.

During the firing process of corundum brick and chrome corundum brick, al2o3-cr2o3 solid solution is formed between the particles, between the particles and the fine powder, and between the fine powder and the fine powder. The solid solution joins the particles and the fine powder together like a bridge to greatly improve the strength of the data. The thermal shock stability takes part in Cr2O3 in corundum, when the content of Cr2O3 is 10% - 66%.

The thermal shock stability of the data decreases with the increase of Cr2O3 content, that is, the CR corundum brick with low Cr2O3 content has better thermal shock stability than that with high Cr2O3 content. The Cr2O3 content of high-performance chrome corundum brick is between 12% and 20%, and its thermal shock stability is better than that of corundum brick; especially, AKZ type chrome corundum brick, which is consumed by taking part in a small amount of phase change additives, has better thermal shock stability.

Display of Hot Products

You may be interested in the following information?