Production technology and application of high alumina refractory brick

发布时间:2020-06-24

浏览:次

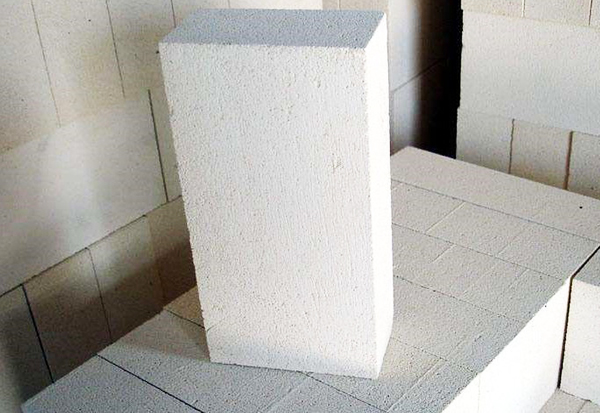

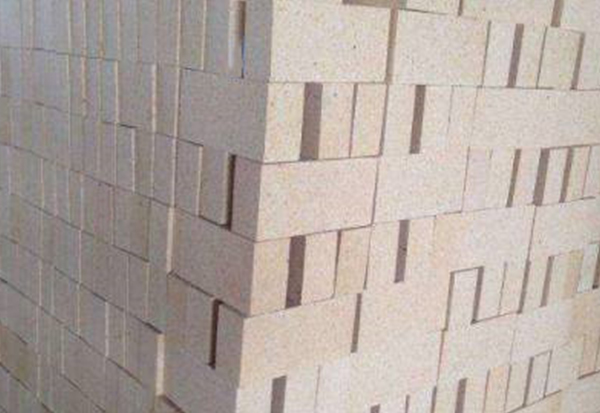

The production process of high alumina refractory brick is similar to that of multi clinker clay brick. The difference is that the proportion of clinker in the ingredients is high, which can be as high as 90-95%. Before crushing, the clinker needs to be sorted and screened to remove iron. The firing temperature is high, such as 1500-1600 ℃ when the tunnel kiln is used for firing high alumina bricks such as I and II.

Raw materials of high alumina refractory brick

According to different resource conditions and product requirements, the following types of raw materials can be used: high alumina bauxite mainly composed of hydrous alumina minerals (alumina monohydrate, alumina trihydrate, etc.); sillimanite minerals (including kyanite, andalusite, sillimanite, etc.); artificial synthetic raw materials, such as industrial alumina, synthetic mullite, fused corundum, etc. China is rich in bauxite resources with good texture, and its producing areas are mainly in Shanxi, Henan, Hebei, Guizhou, Shandong and other places. The bauxite produced is mainly a mixture of two minerals, a-Al2O3 · H2O and kaolinite.

Characteristics of high alumina refractory brick

a. Fire resistance

The refractoriness of high alumina brick is higher than that of clay brick and semi silica brick, reaching 1750 ~ 1790 ℃, which belongs to high-grade refractories.

b. Load softening temperature

Because of the high content of Al2O3 in the high aluminum products, less impurities and less fusible glass, the load softening temperature is higher than that of clay brick.

c. Slag resistance

There are more Al2O3 in the high alumina brick, which is close to the neutral refractory and can resist the erosion of acid slag and alkaline slag. Because SiO2 is contained in the brick, the ability of resisting alkaline slag is weaker than that of resisting acid slag.

Application of high alumina refractory brick

High alumina refractory brick is mainly used for lining blast furnace, hot blast furnace, electric furnace top, blast furnace, reverberatory furnace and rotary kiln. In addition, high alumina brick is widely used as open hearth heat storage lattice brick, plug head for pouring system, nozzle brick, etc. But the price of high alumina brick is higher than that of clay brick, so it is unnecessary to use high alumina refractory brick where clay brick can meet the requirements.

Display of Hot Products

You may be interested in the following information?