Explain the variety of lower castable and common construction methods

发布时间:2020-06-24

浏览:次

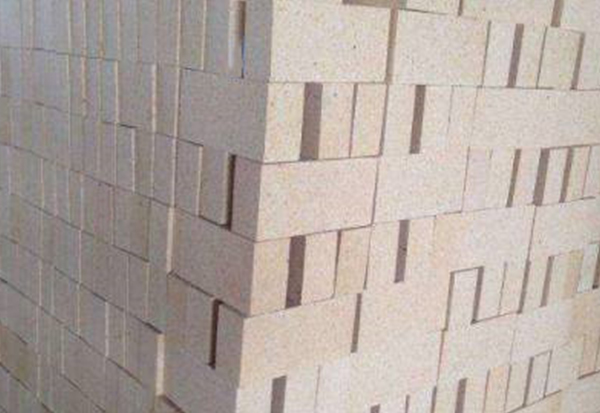

Castable is one of the fire-resistant materials. It is widely used in the manufacture of refractory bricks and some prefabricated parts. It can also be used in the lining of industrial kilns. The castable is easy to construct and has good integrity. It is mainly formed by pouring, and can be separated from all materials according to the use of strips.

In application, the following section introduces the varieties of castables and common construction methods. 1. The varieties of refractory castables are divided according to their characteristics: high-strength wear-resistant castables, high-temperature resistant castables, Low Cement Castables, steel fiber castables, acid resistant and heat-resistant castables and other castables with characteristics, which are divided according to refractory materials.

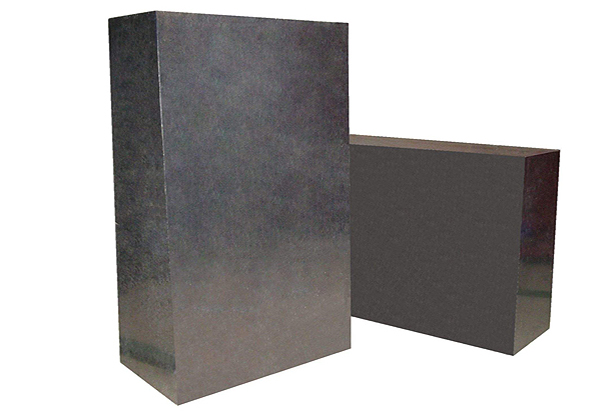

Clay castables, high alumina castables, siliceous castables, mullite castables, corundum castables, silicon carbide castables, etc. are classified according to the applicable industrial kiln environment: aluminum silicon carbide castables for the iron ladle tapping ditch, aluminum magnesium spinel castables for the ladle, etc. are classified according to the density: light castables and heavy castables, and according to the composition of the separating agent.

Organic separation castables and inorganic separation castables, such as resin separation castables, cement separation castables, divided by chemical properties: acid resistant castables, neutral castables, alkali resistant castables, common construction methods and pouring construction methods of refractory castables, inspection: check whether the mold can be supported, whether there are gaps and deviations, and clear the sundries in the mold.

Whether the anchor (heat-resistant stainless steel palladium nail) can be welded firmly, the external surface of the anchor shall be coated with paint or wrapped with plastic bags to buffer the shrinkage force after heating. Pouring: pour the mixed castable into the mold, insert the vibrator to vibrate, move the vibrator at an average speed, and pull it out slowly. If the pouring area is too large, it can be poured in layers and parts, and can be interleaved.

Display of Hot Products

You may be interested in the following information?