Six main uses of bauxite clinker

发布时间:2020-06-24

浏览:次

Six main uses of bauxite clinker

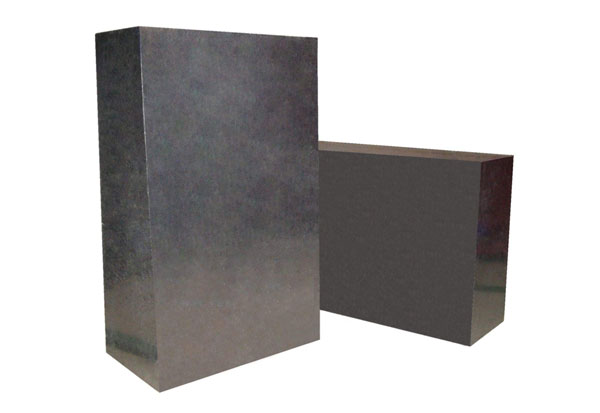

At present, high alumina bauxite clinker powder is a new type of high-grade refractory material, with high aluminum content, low iron content, high hardness, small coefficient of thermal expansion, high refractoriness, stable thermochemical properties and other excellent characteristics. It is suitable for aluminum smelting industry, precision casting, refractory products, grinding materials and other industries.

The common granularity of bauxite clinker process is: 10-20 mesh, 16-30 mesh, 30-60 mesh, 40-70 mesh, 70-100 mesh, 170 mesh, 200 mesh, 250 mesh, 300 mesh, 320 mesh, etc. (special requirements can be customized)

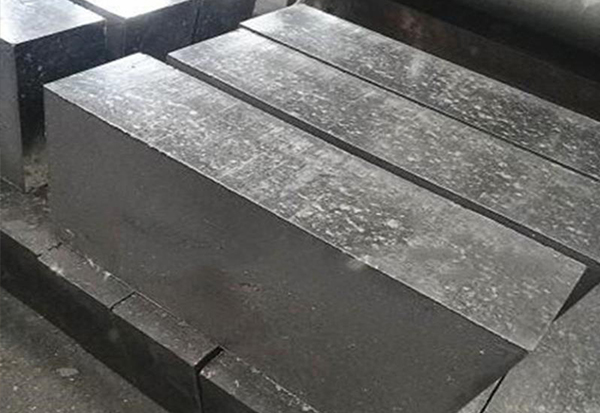

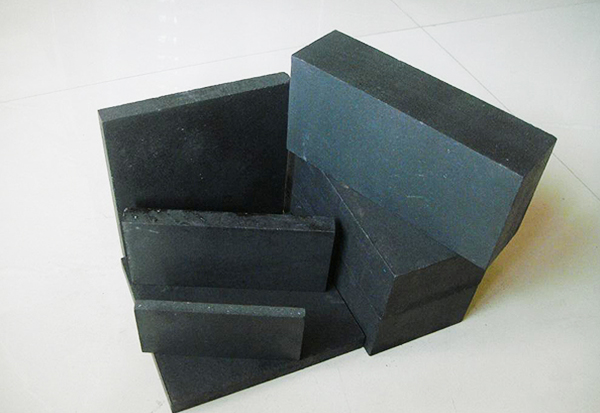

High alumina clinker can be divided into high alumina aggregate and high alumina fine powder according to its shape

Use of bauxite clinker:

(1) Aluminum industry. It is used in national defense, aviation, automobile, electrical appliances, chemical industry, daily necessities, etc.

(2) Precision casting. The bauxite clinker is processed into fine powder and made into a mold for precision casting. For military, aerospace, communications, instrumentation, machinery and medical equipment departments.

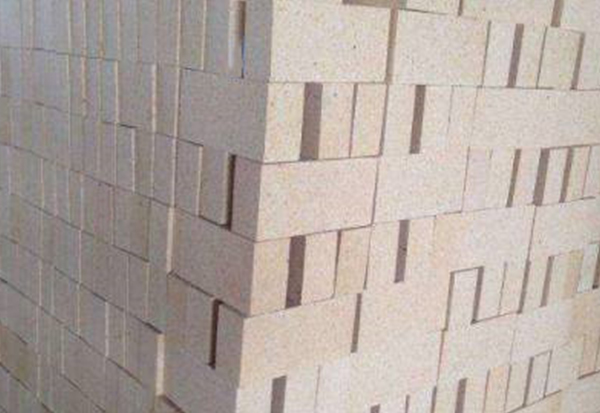

(3) For refractory products. The high alumina clinker has a fire resistance of 1780 ℃, strong chemical stability and good physical properties.

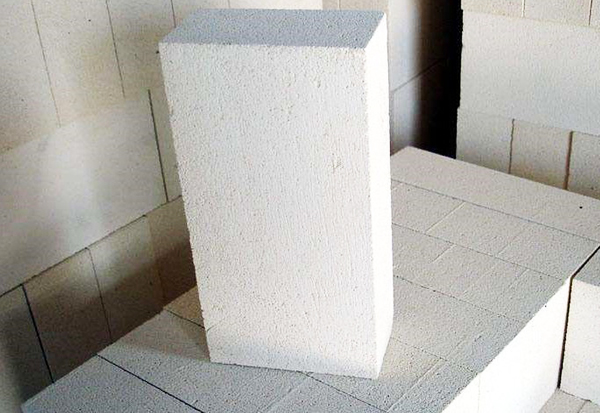

(4) Aluminum silicate refractory fiber. It has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, small heat capacity and mechanical vibration resistance.

(5) Grinding materials, ceramic industry and chemical industry can produce various aluminum compounds.

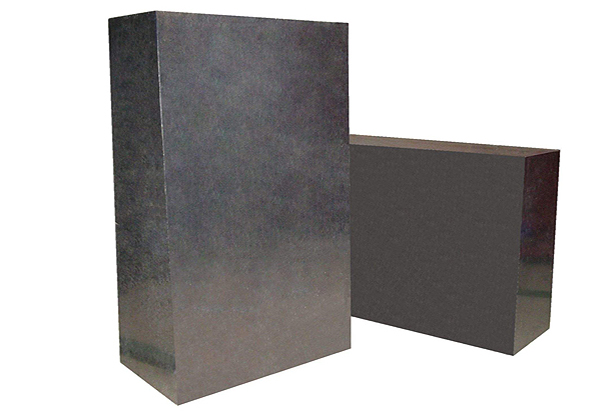

(6) Using magnesia and bauxite clinker as raw materials and adding proper binder, the effect of the whole lining of the ladle is very good.

Display of Hot Products

You may be interested in the following information?